Managing CO2 flow rate satisfactorily is particularly difficult for smaller aquariums; it’s very easy to have the CO2 come blasting out, but a nice steady well-controlled bubbling takes some work. The usual combination of regulator and needle valve can work, and adding in a secondary flow restrictor between the two can be a big help.

Mott porous metal flow restrictors

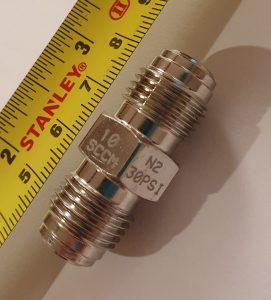

Plastic flow restrictors that work “well enough” can be had for as little as £5, but I’ve always been enamoured of the porous metal flow restrictors from Mott corporation. A metal disc has hundreds of microchannels fabricated into it such that the gas has to squeeze through to the other side. By controlling the size and number of the channels and the shape of the disc, any desired flow rate can be achieved for a defined gas supplied at a defined pressure. I managed to score the pictured one from Ebay.

Fireplace Aquarium Mott flow restrictor

Mott calibrates the flow rate against nitrogen gas with an input pressure of 30 PSI which is a typical regulated gas output working pressure. The one I got is calibrated to 10 SCCM (standard cubic centimetres per minute) which is to say, 10 ml. CO2 is less viscous than nitrogen, so this restrictor outputs a flow of 12 ml / minute CO2. I find that for the 8 hours per day the CO2 is flowing through the aquarium (controlled by a solenoid on a timer) I need a flow rate of 6 ml / minute CO2, or maybe slightly less, so this is the perfect flow restrictor for this set-up. Given an input flow rate of 12 ml / minute CO2 the needle valve has no trouble at all comfortably getting the flow rate down by the remaining 50% needed. With the new restrictor in place adjusting the needle value smoothly moves the flow rate up and down, with none of the twitchiness exhibited with much higher input flow rates.

Installing the restrictor

It wasn’t obvious to me what type of screw threads were on the restrictor. Ultimately, I needed the restrictor attached to a fitting that could connect to the 6 mm OD / 4 mm ID tubing I use for CO2. It turns out the threads on this restrictor mate to a 1/4″ Swagelok VCR metal gasket face seal fitting. I picked up the needed female nuts (SS-4-VCR-1), metal gaskets (SS-4-VCR-2-VS) and adaptor glands (SS-4-VCR-3-6MTA) that would connect the restrictor on each side to a stainless steel 6 mm OD tube. The Swagelok fittings wound up costing about as much as the restrictor. After some debate over how to connect the 6 mm OD / 4 mm ID plastic tubing to the 6 mm OD stainless steel tubes (pro tip: the seemingly obvious choice of 6 mm push fit straight connectors doesn’t work because the connectors can grip the plastic, but not the metal) it turned out the 4 mm ID plastic tubing could be simply stretched over the 6 mm OD metal tubing to provide a simple and convenient connection with no leaks. In the picture the flow restrictor is what looks like a hex nut in the centre of the set-up.

I tested the output of the CO2 past the restrictor when connected to the regulator with no downstream needle valve and everything seems to be functioning as designed.

Read the fine print on the restrictor

I had been monitoring the second-hand shops for a while but hadn’t ever seen a restrictor on offer with a flow rate as low as the 10 SCCM on this one. Most were a lot higher. Some are also calibrated in SLM – standard litres per minute – rather than SCCM, and sometimes calibrated against gasses other than nitrogen which would need a different gas viscosity correction factor. Just be sure if you get one it will have a flow rate that is fit for purpose.